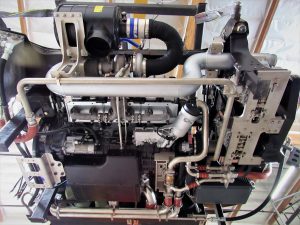

Specialties

Locomotive Climate Solutions performs all repair and overhaul work in-house, utilizing the most current and technologically advanced testing and machining equipment. This allows LCS to accommodate varying customers’ needs from start to finish, customizing the scope of work to varying units’ needs.